Saarland Co-operation, ALAS, MESEMA

Saarland Co-operation

In all activities Prof. Janocha places great value in the practical applicability of his department's research content. Numerous contacts to the industry and successful national and international joint projects (example below) substantiate this ambition.

At the beginning of 1993, the consulting centre "Neue Aktoren mit MikroSystem- und Signalverarbeitungskonzepten" was established with the support of the German Ministry for Research and Technology. With the cessation of the project funds, the consulting centre was transformed into the consulting company "Dienstleistungsgesellschaft für Automatisierungs- und

Signalverarbeitungssysteme" (D*ASS mbH); at the same time robotics was being established as an additional business branch. Ever since, D*ASS mbH has been transforming research results obtained by the LPA into industrial applications.

iMAR GmbH, located in St. Ingbert, and IBP GmbH in Saarlouis are two other spin-off companies that actually have their roots in the LPA and were founded by former staff members. By now, iMAR has become the international market leader in the field of measuring and navigation systems; IBP is developing hardware and software for industrial measuring devices and process automation.

In spring 1996 the consulting centre, the LPA and related departments moved into the "Zentrum für Innovative Produktion" ZIP

(Centre for Innovative Production) on the grounds of the "IT Park Saarland", which is located in Saarbrücken, Burbach. Its huge workshop and expansive testing area gives interested enterprises an additional opportunity to profit directly from the knowledge and technology resources of the laboratories and institutes located in the ZIP.

|

ALAS

The properties required in an automobile's motor mount are often fairly contradictory: on the one hand, oscillations which lie within the range of the motor's eigenfrequencies are coupled into the car's chassis and must be dampened by means of a motor mount with a high stiffness in order to guarantee a good driving comfort. On the other hand, oscillations of higher frequencies emerge when the engine is running above idle speed. They too need to be decoupled from the passenger compartment, which, however, requires a mount with the lowest possible stiffness. These requirements were answered by the development of the hydro mount, which went into full-scale production for the first time in 1997.

Within the framework of the research project ALAS (Contract Reference 03N3105) funded by BMBF (Federal Ministry of Education and Research) and initiated by Professor Janocha, a completely new generation of hydro mount was developed: the MR fluid hydro bearing, which is an innovative and flexible electrically controllable motor mount system for the automobile industry. The main feature of this novel mount is a magnetorheological (MR) fluid, acting as a hydraulic fluid. This fluid contains small magnetisable particles, and by applying controllable magnetic fields to the fluid, the mount stiffness can be varied continuously over a wide frequency range. Due to the high reaction speed of the MR fluid, hydro mounts based on MR fluids adapt to fast changing operating conditions.

During the final project phase (at the end of 2004), the new multifunctional mount was employed and successfully tested in an experimental vehicle by BMW, one of the six consortium partners.

MESEMA

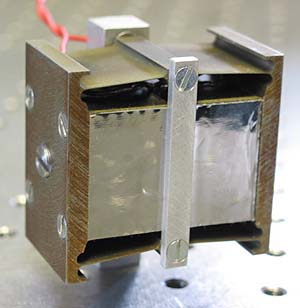

Building on the successful development results achieved during the preceding project MESA (see foto), the LPA and its Actuator Group at the Centre for Innovative Production is working since January 2004 on the further development of actuator technologies based on magnetoelastic materials within the scope of the three-year EU project MESEMA ("Magnetoelastic Energy Systems for Even More Electric Aircraft", www.mesema.info).

The 18 partners in the project consortium want to exploit the advantages of the powerful active magnetic materials by applying innovative solutions in several aeronautic applications (see German article in Saarland University's campus aktuell PDF-File, 230 KB). In particular, LPA is working primarily on the development of actuators, power electronics and a hysteresis compensation module for reducing structural vibrations in passenger aircraft and helicopters. Furthermore, advancements are being made in the relatively new field of energy harvesting, making use of solid-state actuators to generate electricity from structural vibrations.

|

- The magnetostrictive dynamic vibration absorber developed in the MESA project has been patented.

- Businesses interested in commercial exploitation are being sought.

|

|